In steel structure design, the challenge is not only to achieve a functional or aesthetic form, but to reach an engineering solution that balances strength, efficiency, and cost.

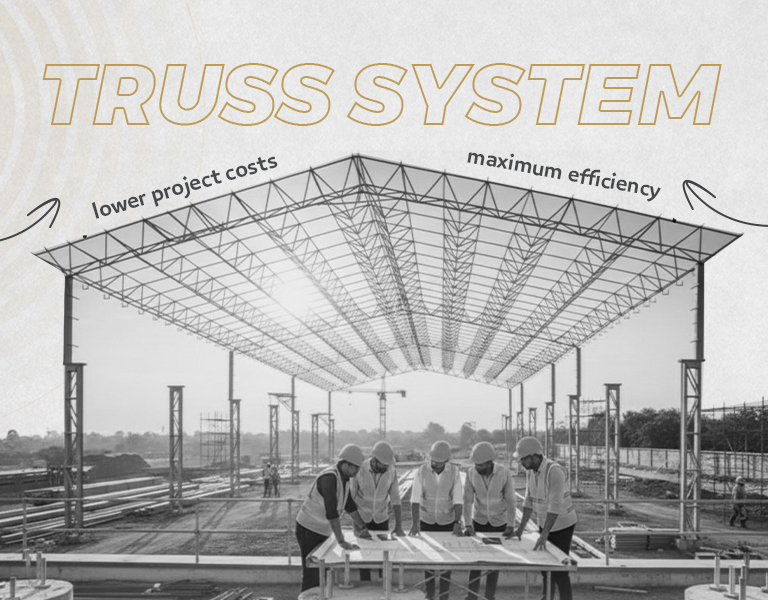

Among the most effective structural systems used worldwide, steel trusses stand out as a smart and practical choice—especially for industrial buildings with large spans.

to watch video click here

Steel Trusses: More Than Just Geometric Shapes

Steel trusses may appear as repetitive triangular forms, but in reality, they represent a highly efficient structural system.

They are commonly used when large spans are required without intermediate columns, allowing maximum flexibility for industrial, storage, and production spaces.

The Structural Principle Behind Trusses

The efficiency of trusses comes from a simple but powerful concept:

Distributing loads through multiple small members instead of one massive element.

This load distribution reduces internal forces and allows the use of smaller steel sections, resulting in:

-

Lower total structural weight

-

Reduced steel consumption

-

Higher structural efficiency

Practical Example: 30-Meter Span Warehouse

Let’s consider an industrial warehouse with a 30-meter clear span, required to be covered without internal columns.

Option 1: Without Using Steel Trusses

-

Heavy steel girders with large cross-sections

-

High steel weight

-

Higher fabrication cost

-

Difficult transportation

-

Longer erection time

-

Larger cranes required on sit

Option 2: Using a Steel Truss System

-

Loads distributed among multiple members

-

Reduced steel weight

-

Smaller and more economical sections

-

Easier transportation

-

Faster installation

-

Lower crane capacity requirements

Understanding the True Cost of Steel Structures

A critical point often overlooked is:The cost of a steel structure is not defined by steel price alone.

The total cost includes:

-

Fabrication

-

Transportation

-

Lifting and erection

-

Installation time

-

Equipment and crane requirements

Steel truss systems frequently lead to lower total project costs, even if the steel price per ton appears similar.

At HasanOğlu, we do not select structural systems based solely on design trends or appearance.

Our focus is on engineering solutions that deliver maximum efficiency and optimal cost in real construction conditions.

With our experience in designing and manufacturing steel structures in Turkey, we ensure:

-

Careful evaluation of each project’s requirements

-

Selection of the most suitable structural system

-

A balanced approach between safety, performance, and economy