Design Code and Specifications

Design Codes

Hot-rolled structural steel is designed in accordance with AISC or British standard BS 5950.

Built-up frames and other welded members are designed in accordance with the American Institute of Steeel Construction AISC “specification for Design, Fabrication and erection of structural Steel Buildings.

All welding conform to the requirements of American Welding Society.

Light Gauge Cold-formed members are designed in accordance with the requirements of the American iron and Steel Institute “Specifications of the Design of Light Gauge Cold-Formed Steel Structural Members”.

Design Loads

- 1. Live Load

- 2. Prescribed wind load

- 3. Collateral Load and

- 4. Equipment Loads

Material Specification

Hot rolled sections are fabricated from material having a minimum yield stress of 345 N/ mm2 (50 ksi conforming to ASTM A-572 or minimum yield 275N/mm2 conforming to EN10025 S 275.

Flange and Web material for built-up sections, connection plates and stiffeners are fabricated from material having a minimum yield stress of 345 N/mm2 (50ksi conforming to ASTM A572 Grade 50.

All galvanized light gauge cold-formed structural members are fabricated from steel coil having minimum yield stress of 365 N/mm2 with a galvanized coating of 275 g/m2 conforming to JIS G3302 SGH490.

Aluminum Zinc coated steel and pre-painted Galvanized coated steel sheeting, eave Gutter, downspout, Flashing and Trims have a minimum yield strength of 345 N/mm2 (50ksi with approximately 55% aluminum and 45% zinc alloy coating of 150g/m2 (total on both sides, conforming to ASTM A-792 Grade -50B.

Galvanized coated steel and pre-painted Galvanized coated steel sheeting, Eave Gutter, Downspout, Flashing and trims have a minimum yield strength of 345 N/mm2 (50ksi with a ‘galvanized coating’ of 275 g/m2 conforming to ASTM A-653 Grade-50. Aluminum and pre-painted Aluminum Sheeting, Eave Gutter, Downspout, Flashing and Trims have minimum yield strength of 180 N/mm2 (30ksi conforming to Aa-3105-H16.

High tensile bolts conform to the requirements of ASTM A-325.

Diagonal brace rods and anchor bolts have minimum yield strength of 345 N/mm2 (50ksi) conforming to ASTM A-572 Grade-50.

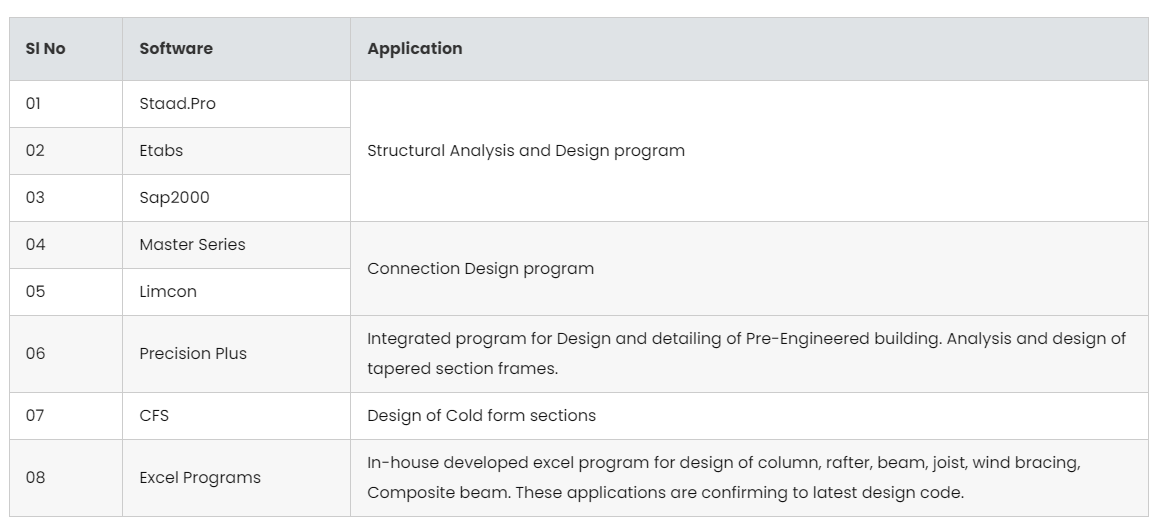

Design Software

| Sl No | Software | Application |

|---|---|---|

| 01 | Staad.Pro | Structural Analysis and Design program |

| 02 | Etabs | |

| 03 | Sap2000 | |

| 04 | Master Series | Connection Design program |

| 05 | Limcon | |

| 06 | Precision Plus | Integrated program for Design and detailing of Pre-Engineered building. Analysis and design of tapered section frames. |

| 07 | CFS | Design of Cold form sections |

| 08 | Excel Programs | In-house developed excel program for design of column, rafter, beam, joist, wind bracing, Composite beam. These applications are confirming to latest design code. |

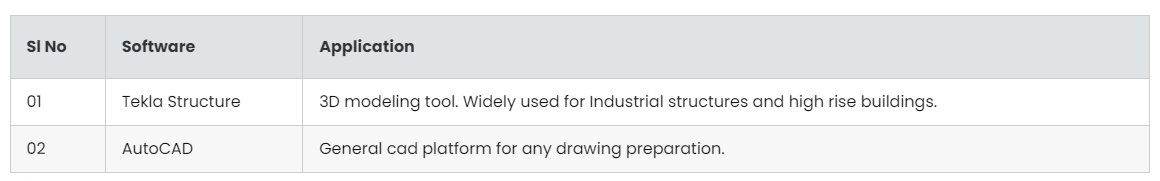

Detailing Software

| Sl No | Software | Application |

|---|---|---|

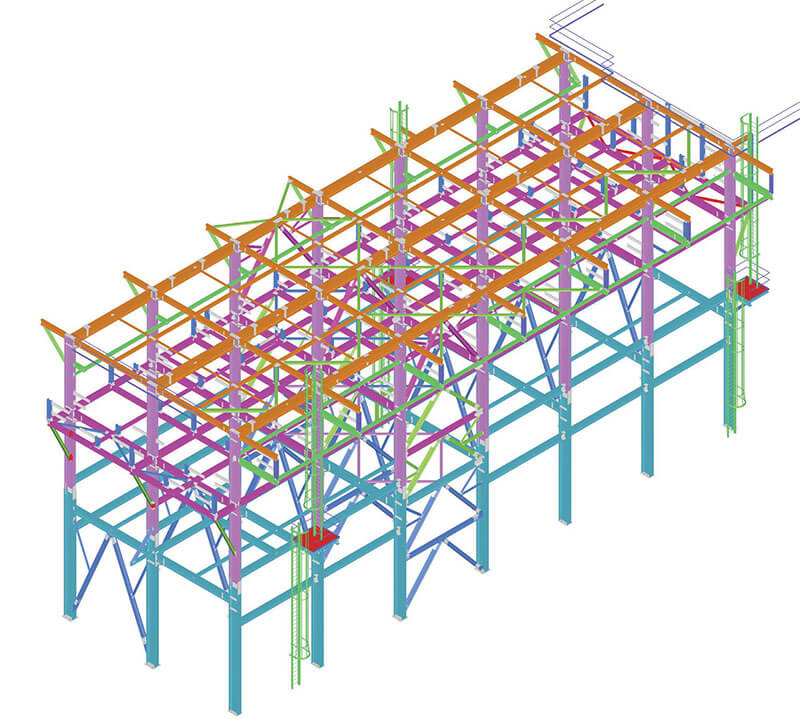

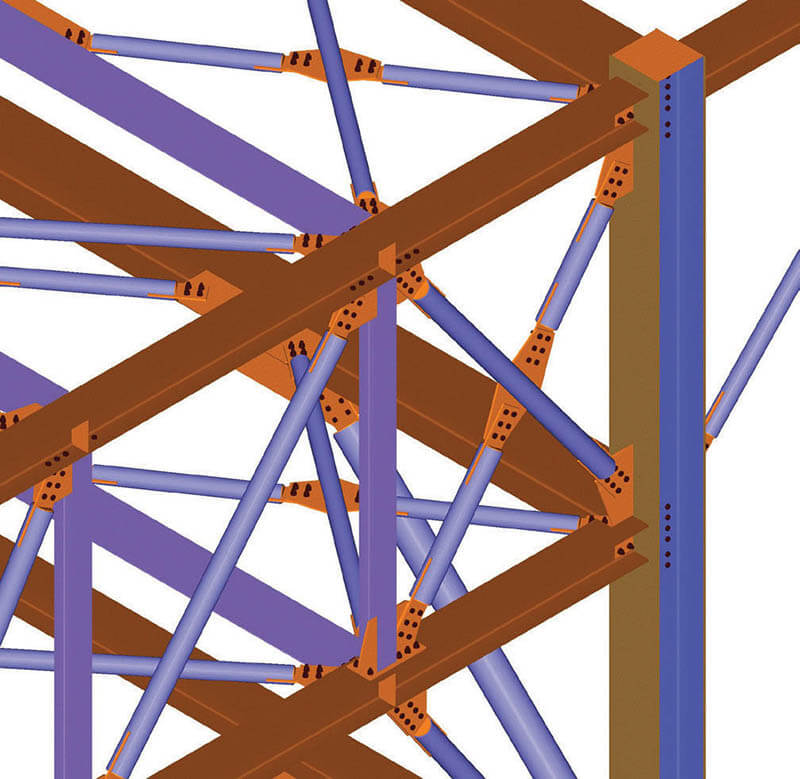

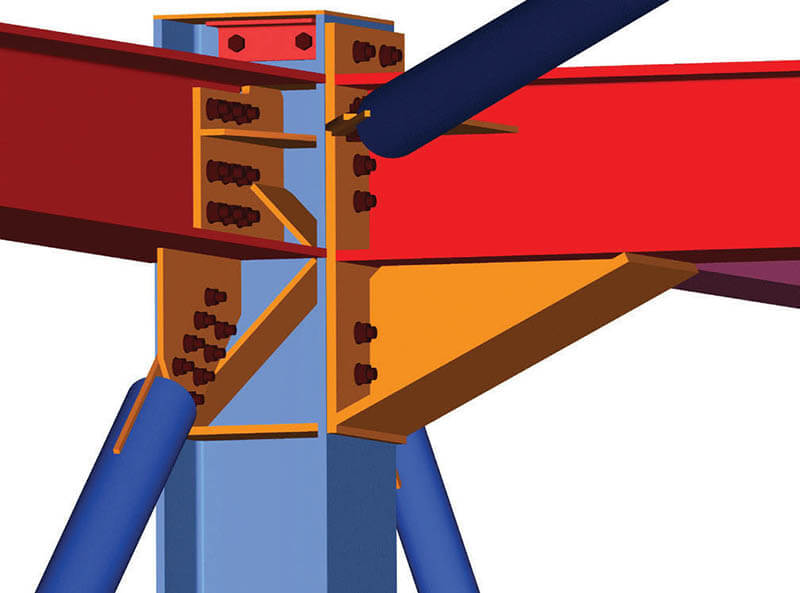

| 01 | Tekla Structure | 3D modeling tool. Widely used for Industrial structures and high rise buildings. |

| 02 | AutoCAD | General cad platform for any drawing preparation. |

Hot Rolled Structures

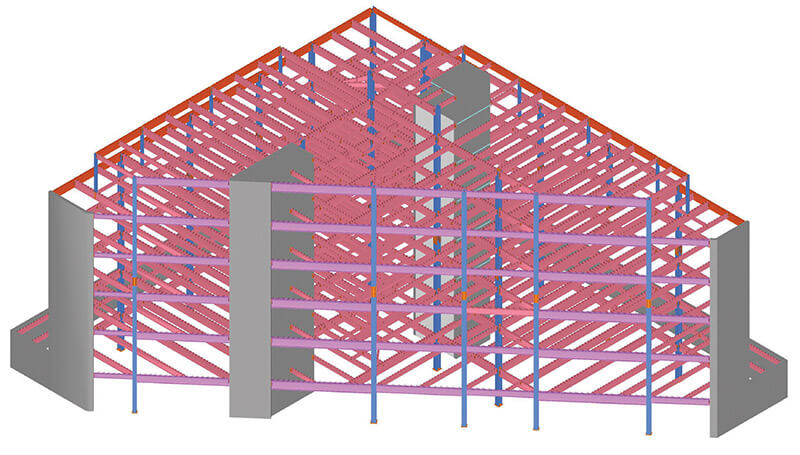

Industrial Structures and Buildings

The engineering, the planning the manufacturing and the delivery of HASANOGLU all are large enough as well as suitably flexible to undertake major projects in an effective and competitive manner.

Pipe rack: Supporting structure for Petroleum Gas Pipe line.

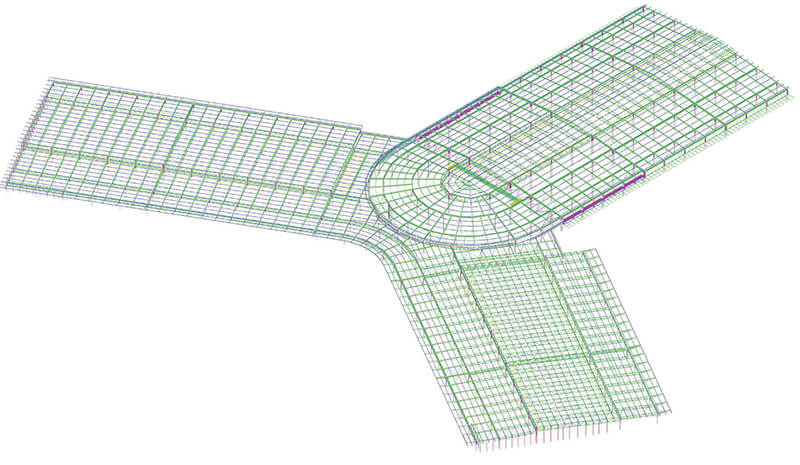

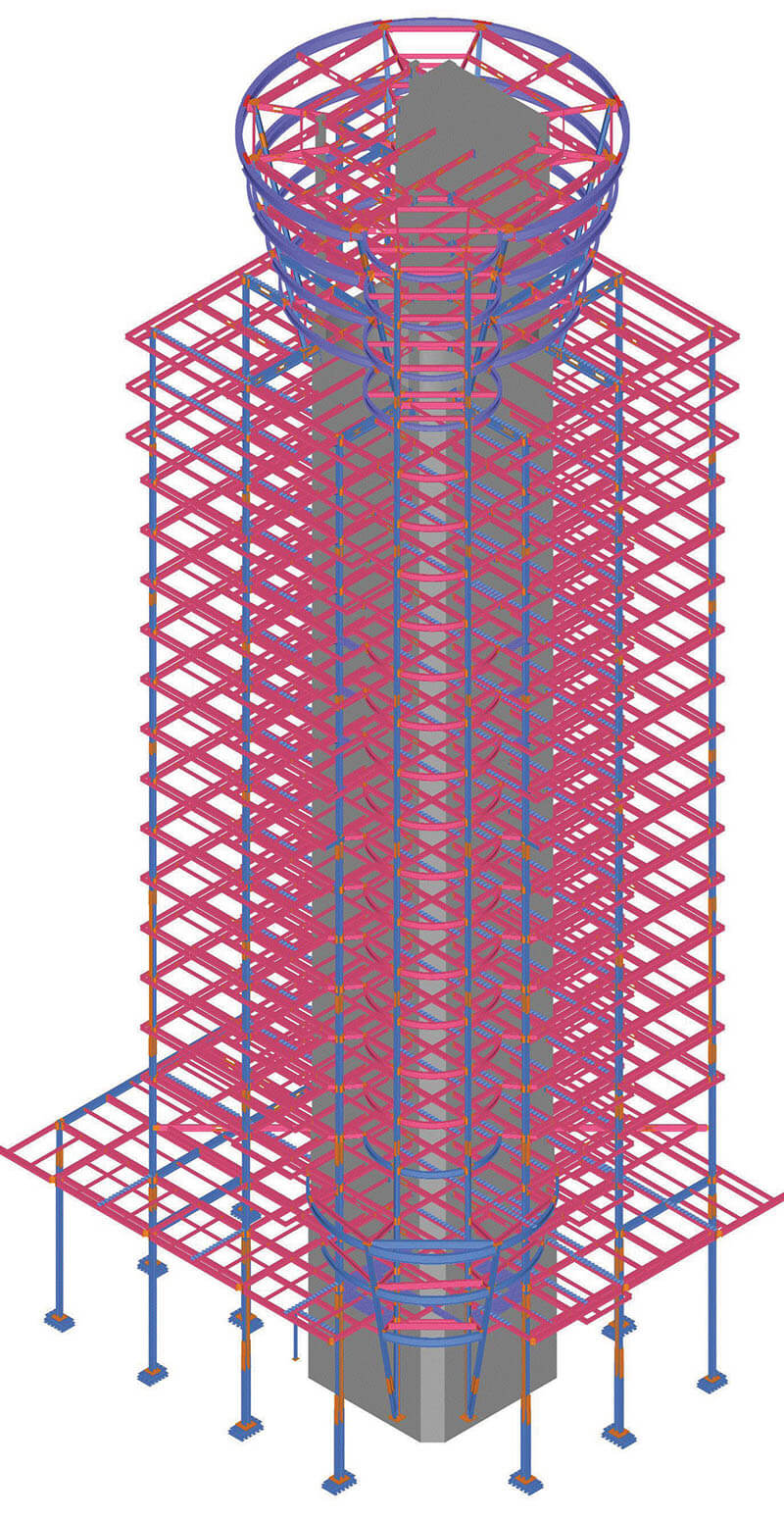

Special Steel Structure

HASANOGLU is capable of handling special type structures with complex shape by nature, for instance, crown structure of a high rise towers, international airport terminal buildings are unique in design and appearance. To meet the uniqueness, steel structure will be designed and modeled with consideration of architectural needs and design code guidance.

Industrial Structures and Buildings

As structural steel manufacturer, HASANOGLU can engineer and manufacture any complex structures and buildings. Tekla structure software has been employed for modeling and generating shop drawing for all complex structures.As structural steel manufacturer, HASANOGLU can engineer and manufacture any complex structures and buildings. Tekla structure software has been employed for modeling and generating shop drawing for all complex structures.

High rise and Low rise Buildings

High and Low rise buildings are usually city block commercial developments. The architectural and aesthetic requirements will control interior and exterior column spacing and therefore grid (bay) size.

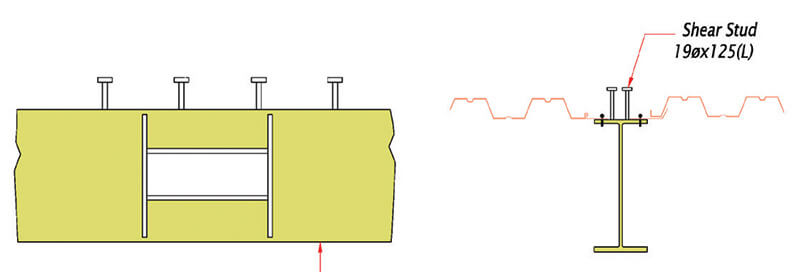

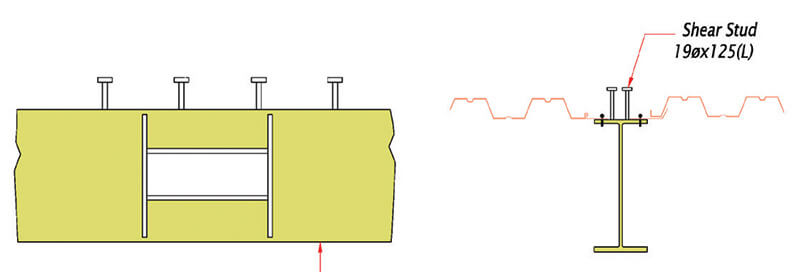

Building framing consists of either two way rigid frame, in a one-way rigid and one-way braced frame or Two way braced frame. The floor deck consists in either:

- a low depth non-composite profiled steel deck supported by joists, beams and intermediate support column, or

- a composite profiled steel deck supported as above, or

- a pre-cast concrete plank, whether hollow core, solid or pre-slab resting on the joists / beams.

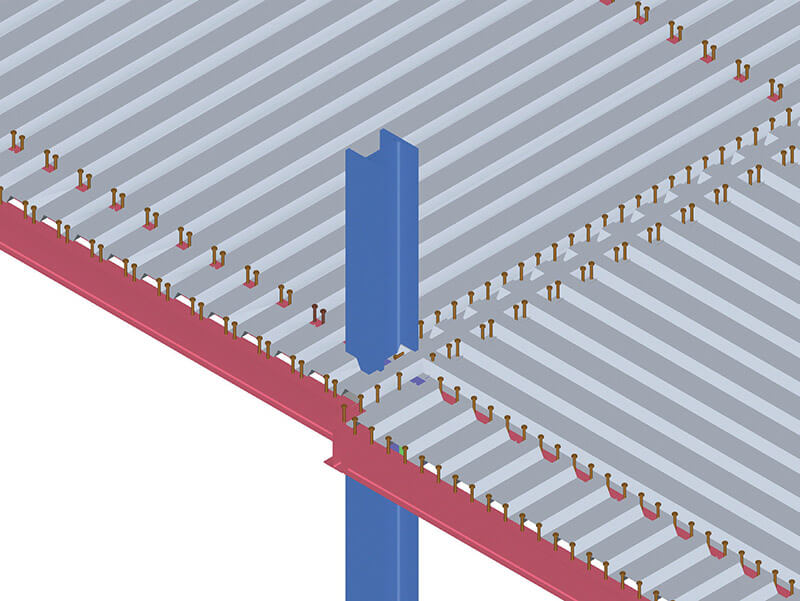

The beams will be typically fitted with studs to ensure composite action along their axis.

Multi-storey structures can be sub-divided into:

- Fully steel framed structures with rigid frame or braced frame systems

- Beam and column steel frames connected to reinforced concrete core or shear wall

Commercial Building: Low rise

building No of Floors: B + G + 4 + P

Building Size: 34.6m x 40.2m

Steel Deck Slab

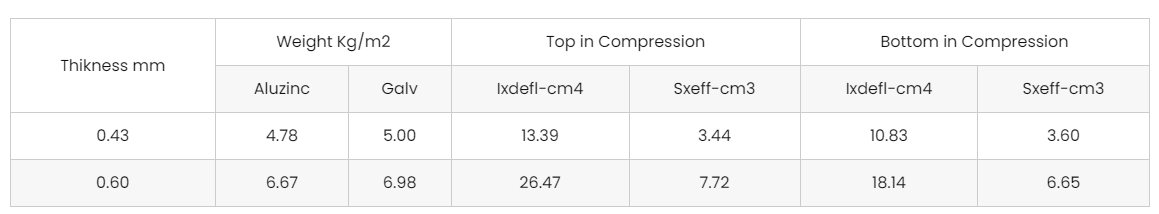

Steel Decking

Thickness: 0.43 mm and 0.60 mm

Coating: Mill finish

Material Specification: Aluzinc sheeting (ASTM A792M GR.50) Galvanized sheeting (ASTM A653GR.50)

Section Properties per meter width

| Thikness mm | Weight Kg/m2 | Top in Compression | Bottom in Compression | |||

| Aluzinc | Galv | Ixdefl-cm4 | Sxeff-cm3 | Ixdefl-cm4 | Sxeff-cm3 | |

| 0.43 | 4.78 | 5.00 | 13.39 | 3.44 | 10.83 | 3.60 |

| 0.60 | 6.67 | 6.98 | 26.47 | 7.72 | 18.14 | 6.65 |

Calculations are based on a minimum yield stress of 345 N/mm² (50 KSI) Thickness refers to metal core (Base Metal Thickness BMT)

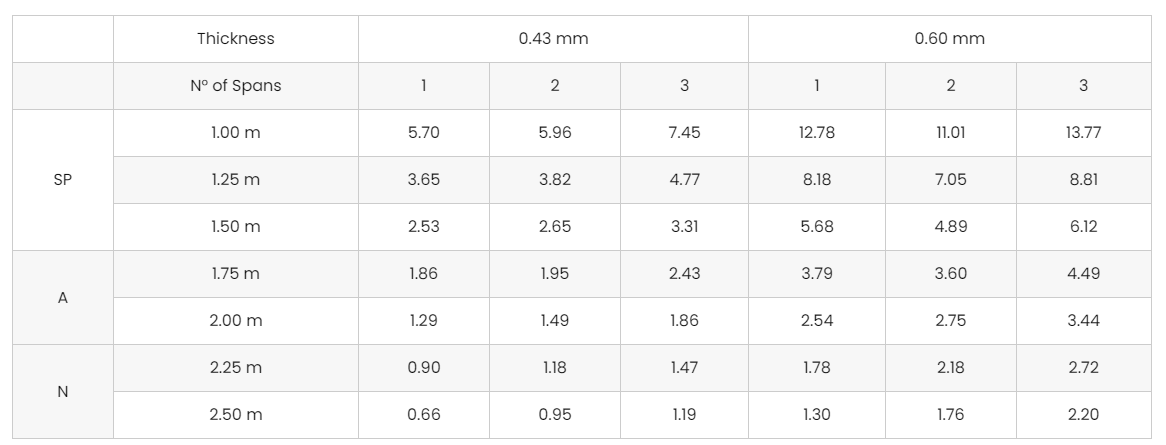

Allowable Load (KN/m²)

| Thickness | 0.43 mm | 0.60 mm | |||||

| N° of Spans | 1 | 2 | 3 | 1 | 2 | 3 | |

| SP | 1.00 m | 5.70 | 5.96 | 7.45 | 12.78 | 11.01 | 13.77 |

| 1.25 m | 3.65 | 3.82 | 4.77 | 8.18 | 7.05 | 8.81 | |

| 1.50 m | 2.53 | 2.65 | 3.31 | 5.68 | 4.89 | 6.12 | |

| A | 1.75 m | 1.86 | 1.95 | 2.43 | 3.79 | 3.60 | 4.49 |

| 2.00 m | 1.29 | 1.49 | 1.86 | 2.54 | 2.75 | 3.44 | |

| N | 2.25 m | 0.90 | 1.18 | 1.47 | 1.78 | 2.18 | 2.72 |

| 2.50 m | 0.66 | 0.95 | 1.19 | 1.30 | 1.76 | 2.20 | |

Note: The allowable loads are due to bending strength or deflection limited of span/200. All stated allowable loads are to include SWT of decking and concrete.

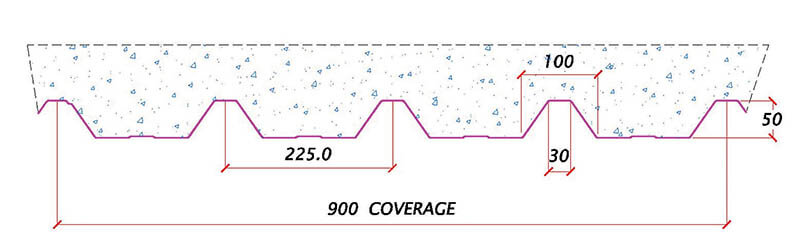

High trough decking panel 75X300

Thickness: 0.80 mm and 1.0 mm and 1.2 mm Mill

Coating: finish

Material Specification: Galvanization to G90 (ASTM A653M-95) Steel Grade SQ-50 (ASTM A653M-95)

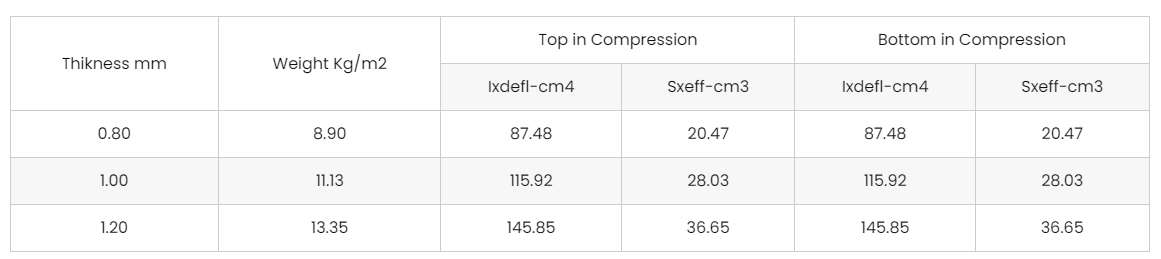

Section Properties per meter width

| Thikness mm | Weight Kg/m2 | Top in Compression | Bottom in Compression | ||

| Ixdefl-cm4 | Sxeff-cm3 | Ixdefl-cm4 | Sxeff-cm3 | ||

| 0.80 | 8.90 | 87.48 | 20.47 | 87.48 | 20.47 |

| 1.00 | 11.13 | 115.92 | 28.03 | 115.92 | 28.03 |

| 1.20 | 13.35 | 145.85 | 36.65 | 145.85 | 36.65 |

Calculations are based on a minimum yield stress of 345 N/mm² (50 KSI) Thickness refers to metal core (Base Metal Thickness BMT)

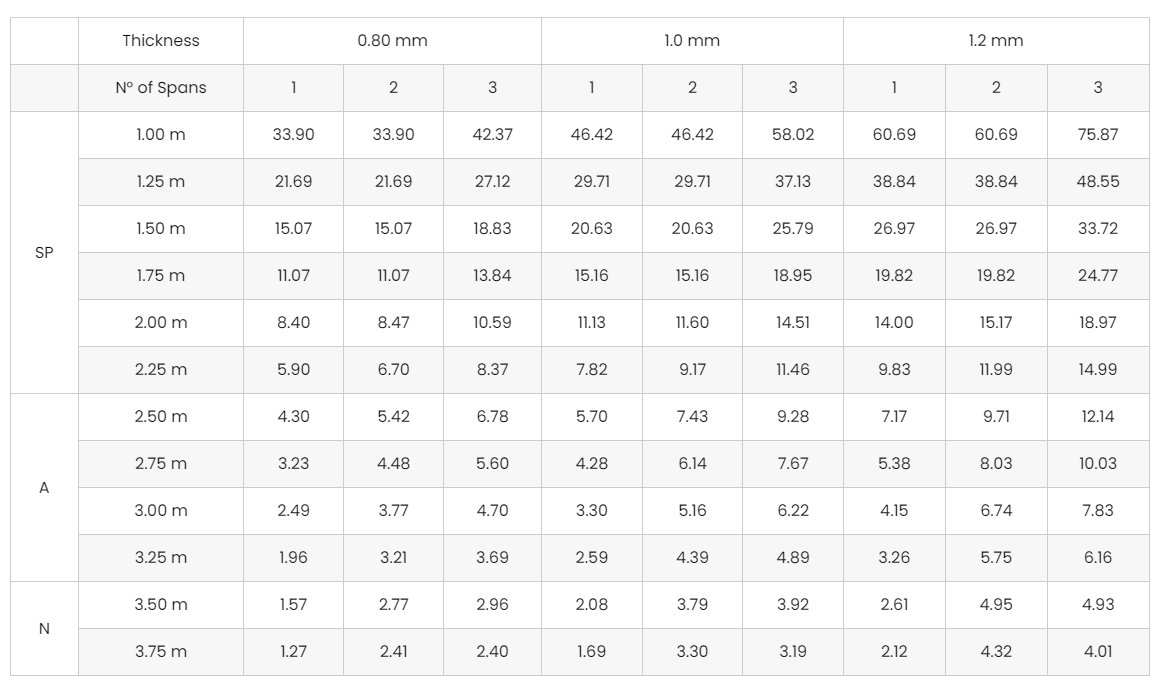

| Thickness | 0.80 mm | 1.0 mm | 1.2 mm | |||||||

| N° of Spans | 1 | 2 | 3 | 1 | 2 | 3 | 1 | 2 | 3 | |

| SP | 1.00 m | 33.90 | 33.90 | 42.37 | 46.42 | 46.42 | 58.02 | 60.69 | 60.69 | 75.87 |

| 1.25 m | 21.69 | 21.69 | 27.12 | 29.71 | 29.71 | 37.13 | 38.84 | 38.84 | 48.55 | |

| 1.50 m | 15.07 | 15.07 | 18.83 | 20.63 | 20.63 | 25.79 | 26.97 | 26.97 | 33.72 | |

| 1.75 m | 11.07 | 11.07 | 13.84 | 15.16 | 15.16 | 18.95 | 19.82 | 19.82 | 24.77 | |

| 2.00 m | 8.40 | 8.47 | 10.59 | 11.13 | 11.60 | 14.51 | 14.00 | 15.17 | 18.97 | |

| 2.25 m | 5.90 | 6.70 | 8.37 | 7.82 | 9.17 | 11.46 | 9.83 | 11.99 | 14.99 | |

| A | 2.50 m | 4.30 | 5.42 | 6.78 | 5.70 | 7.43 | 9.28 | 7.17 | 9.71 | 12.14 |

| 2.75 m | 3.23 | 4.48 | 5.60 | 4.28 | 6.14 | 7.67 | 5.38 | 8.03 | 10.03 | |

| 3.00 m | 2.49 | 3.77 | 4.70 | 3.30 | 5.16 | 6.22 | 4.15 | 6.74 | 7.83 | |

| 3.25 m | 1.96 | 3.21 | 3.69 | 2.59 | 4.39 | 4.89 | 3.26 | 5.75 | 6.16 | |

| N | 3.50 m | 1.57 | 2.77 | 2.96 | 2.08 | 3.79 | 3.92 | 2.61 | 4.95 | 4.93 |

| 3.75 m | 1.27 | 2.41 | 2.40 | 1.69 | 3.30 | 3.19 | 2.12 | 4.32 | 4.01 | |

Note: The allowable loads are due to bending strength or deflection limited of span/20 All stated allowable loads are to include SWT of decking and concrete.

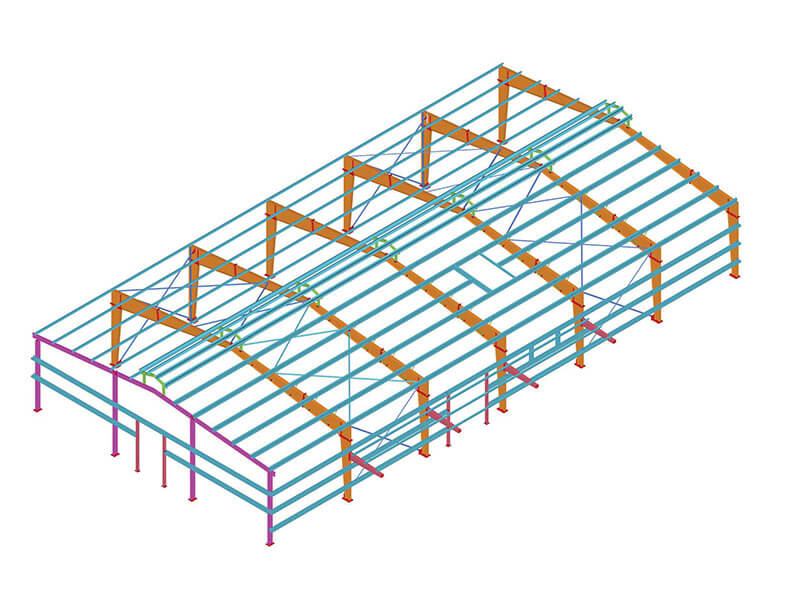

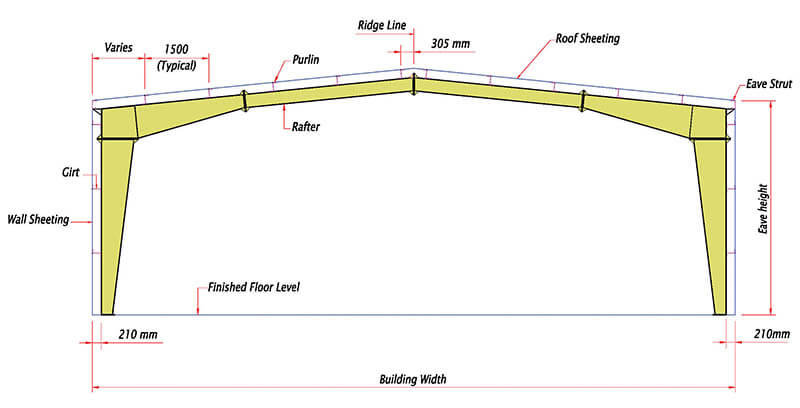

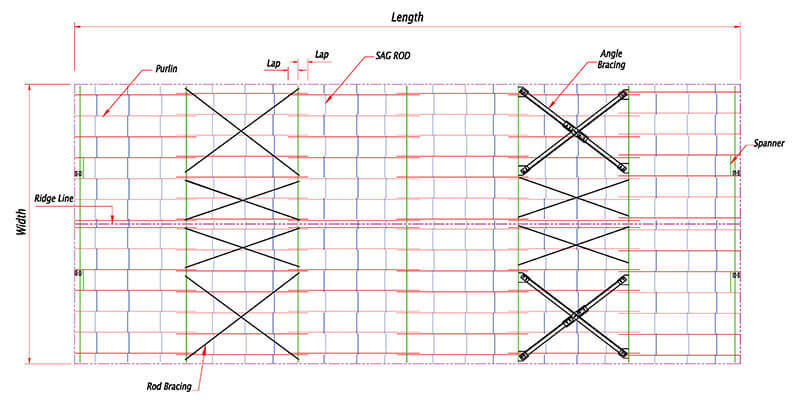

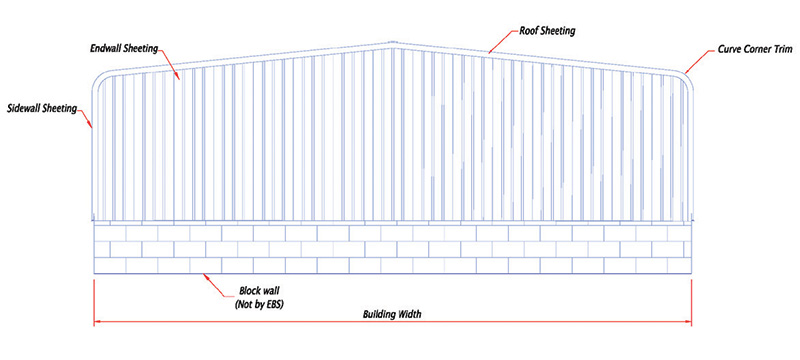

Pre-Engineered Buildings

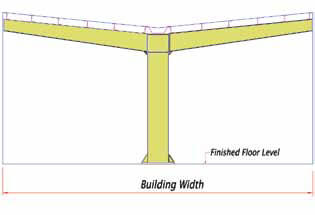

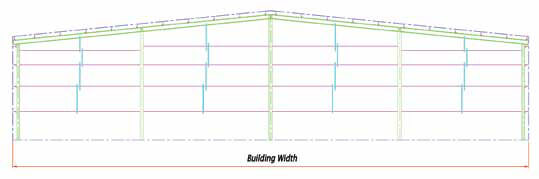

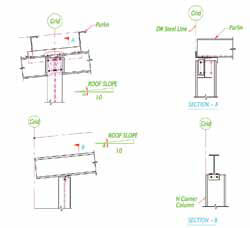

Pre-engineered buildings are defined by the following geometrical parameters: Building width, Length, Eave height, Roof slope, Sidewall bay spacing, End wall bay spacing and Main frame module space. Also design loads are the basic parameter.

Building Length and width are defined by the distance between steel lines. Extreme surface edges of girt and purlin are treated as steel line. Sum of side wall bay spaces will be equal to the building length.

Eave height is the distance from finished floor level to intersection point of roof and sidewall steel line.

Roof Slope is defined as the ratio between vertical distance and horizontal distance of the roof surface. Standard roof slopes are 0.5:10 and 1.0:10

To describe the side wall bay spacing, main frame column spacing to be referred start from back end wall steel line to right end wall steel line. Same way back end wall and front end wall bay spacing to be given from left sidewall steel line to right sidewall steel line.

Primary Main Frames

Pre-engineered buildings offer complete freedom of design to accommodate customers need. HASANOGLU has particularly developed several types to offer optimized economical configuration for customers to choose from according to space, span, crane and architectural requirements.

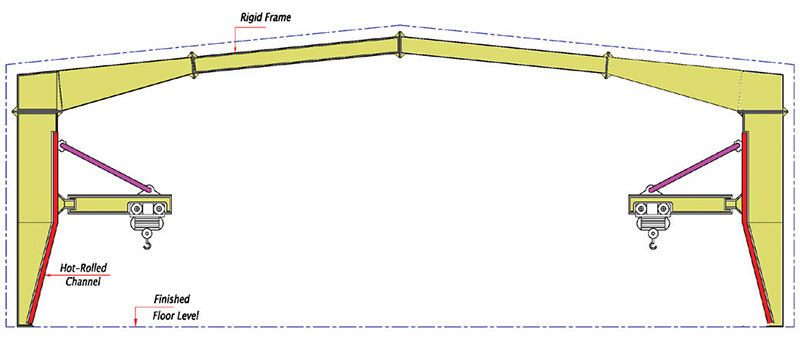

Clear span Frame

When building width is less than 25m, clear span frame will provide un-interrupted clear work space in the building. When building width is more than 25m, it will not be a economical choice to the customer.

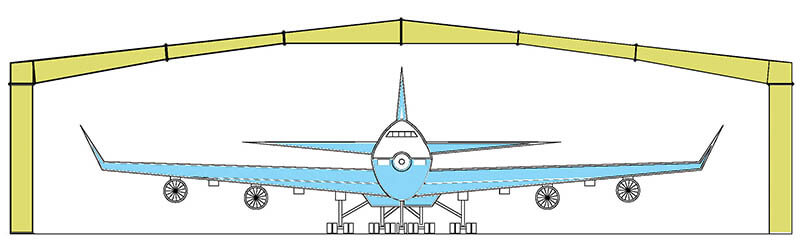

Airport Hangers

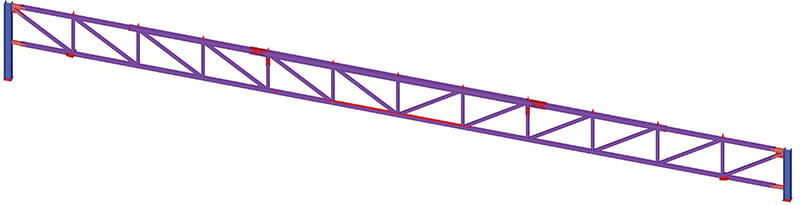

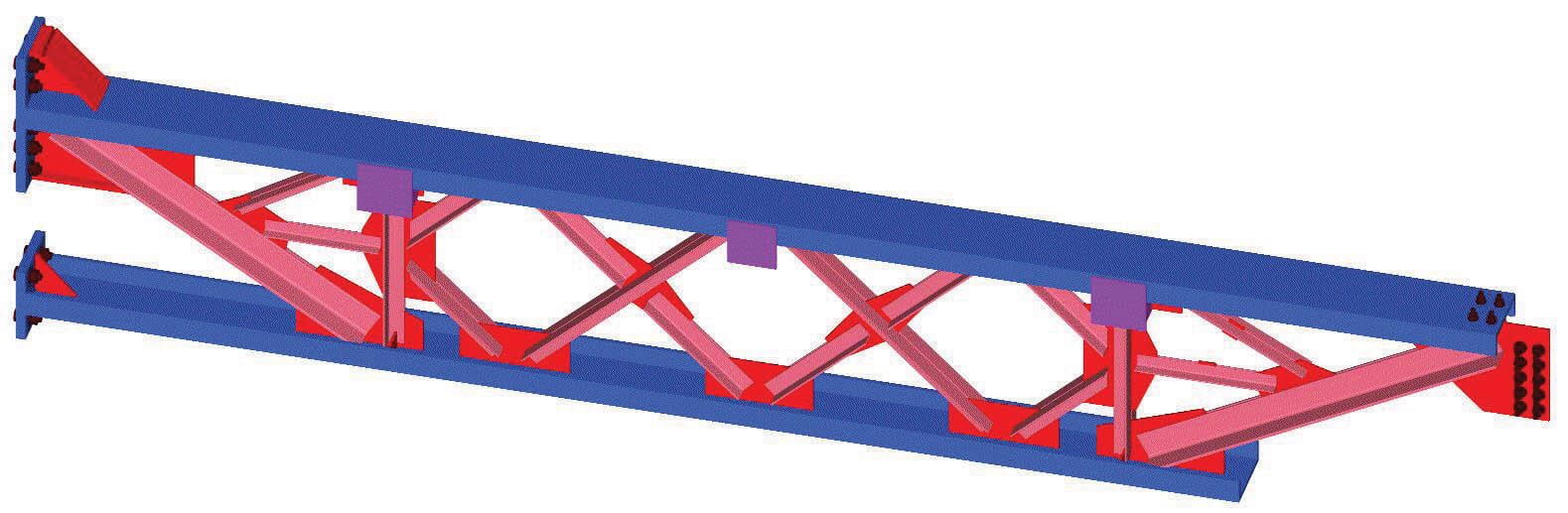

The width of the buildings may vary from 30m to 110m depending upon the number and type of aircraft. Hangers up to 60m clear span are economically built using preengineering building system; however, for span exceeding 60m, a structural truss-column system becomes more economical.

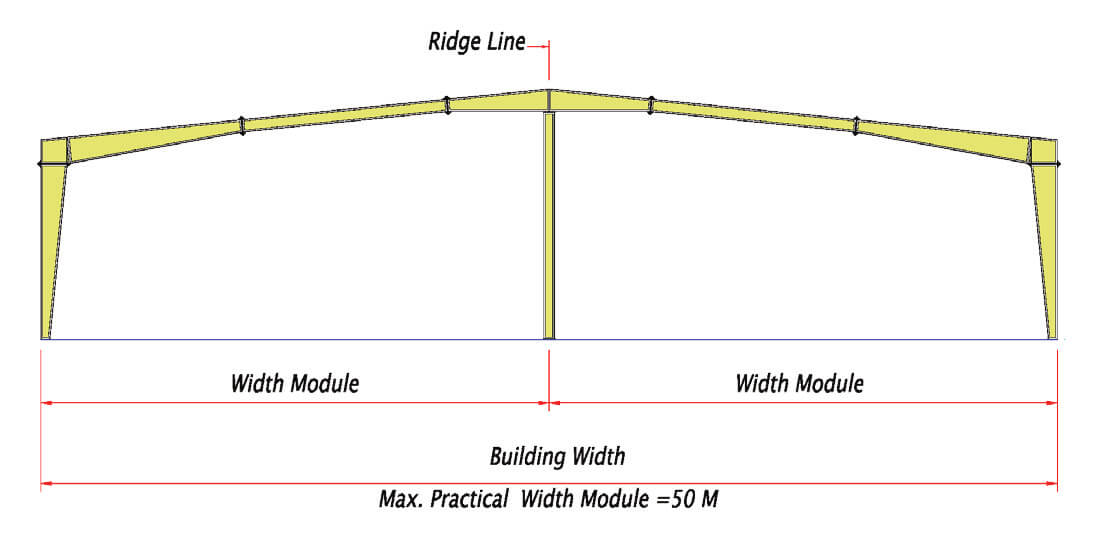

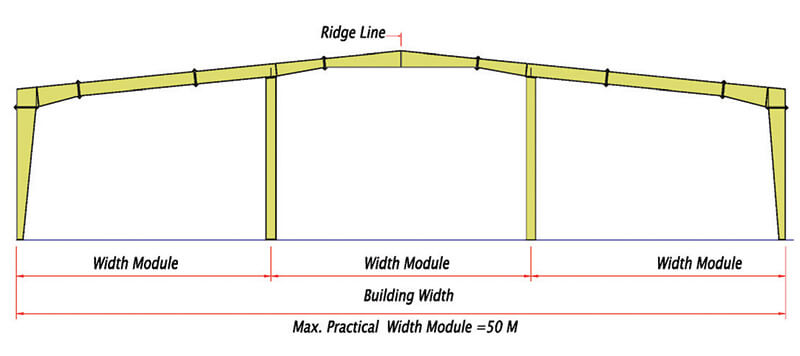

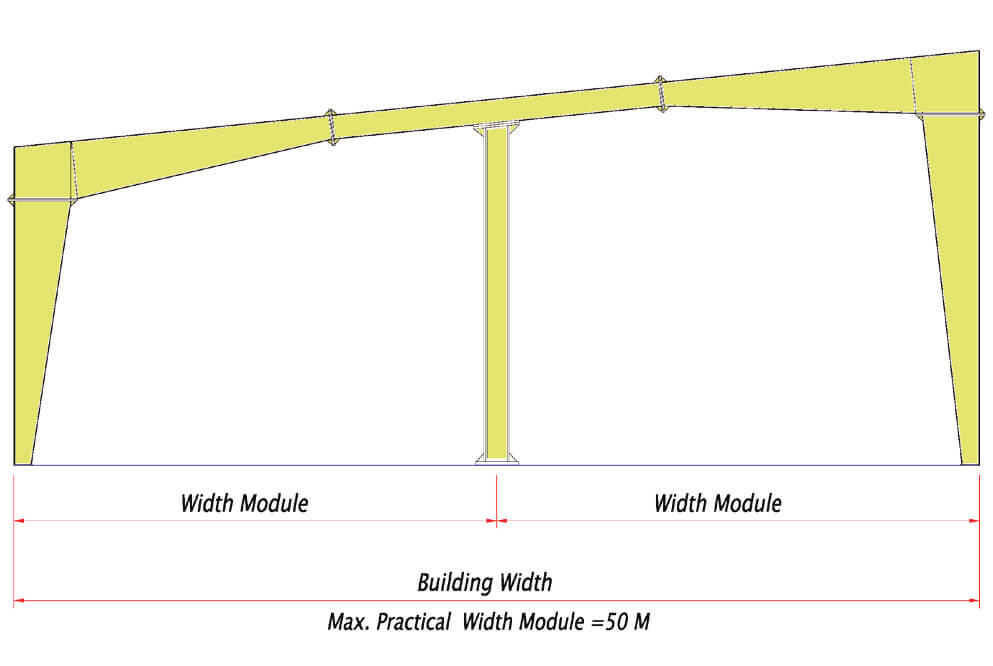

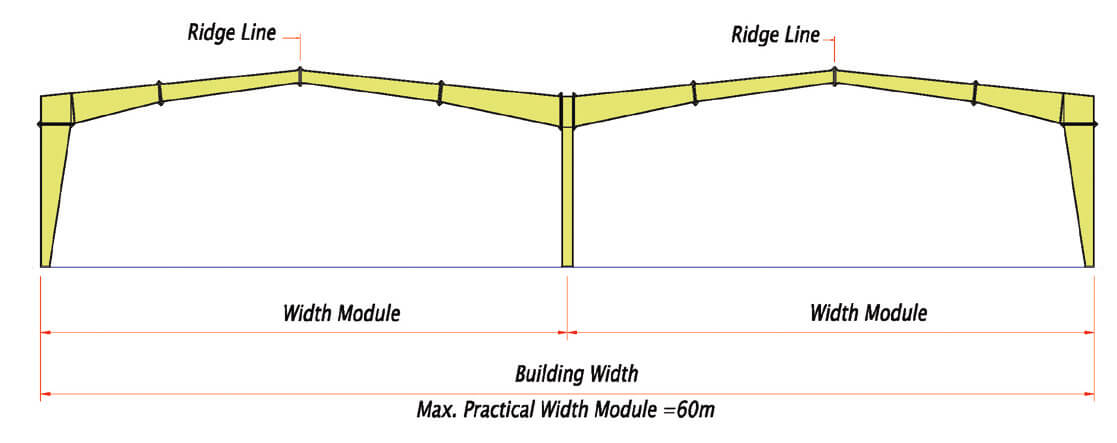

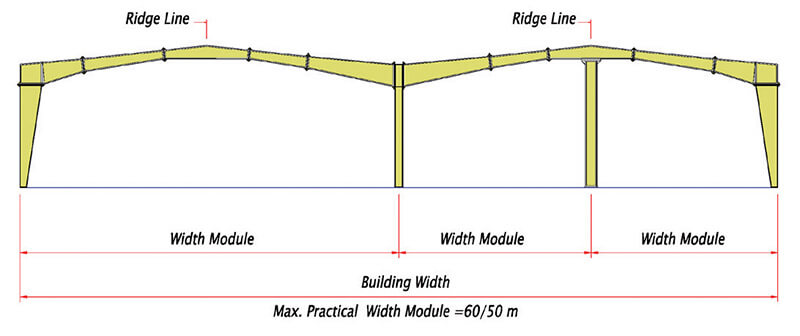

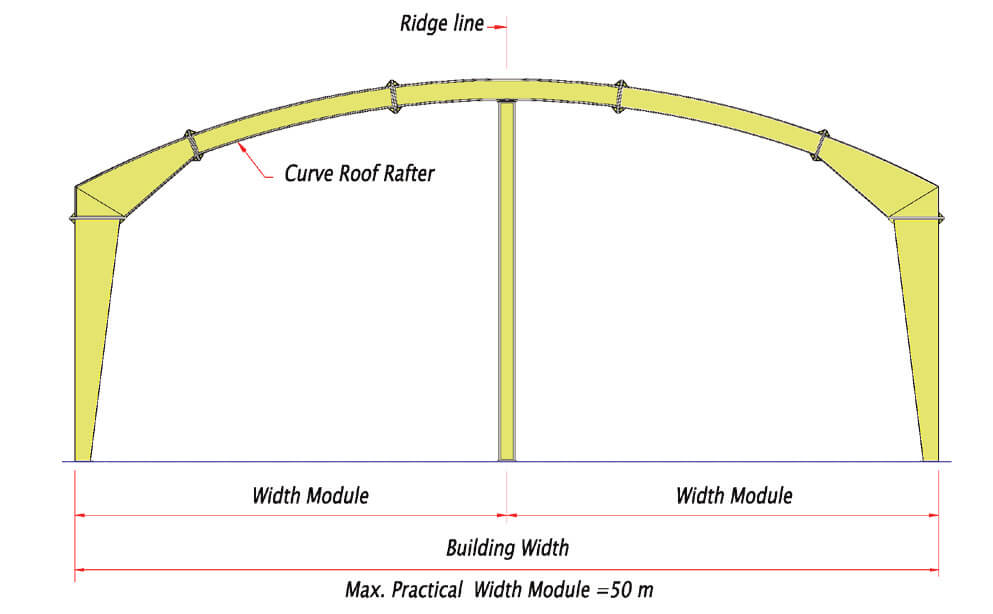

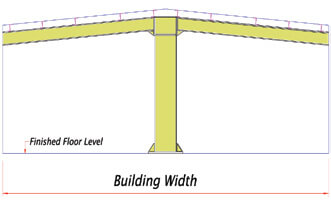

Multispan Frame

The introduction of interior columns allows for grater spans without internal gutters and rainwater pipes. This type of design optimizes bay spacing, building weight and therefore cost.

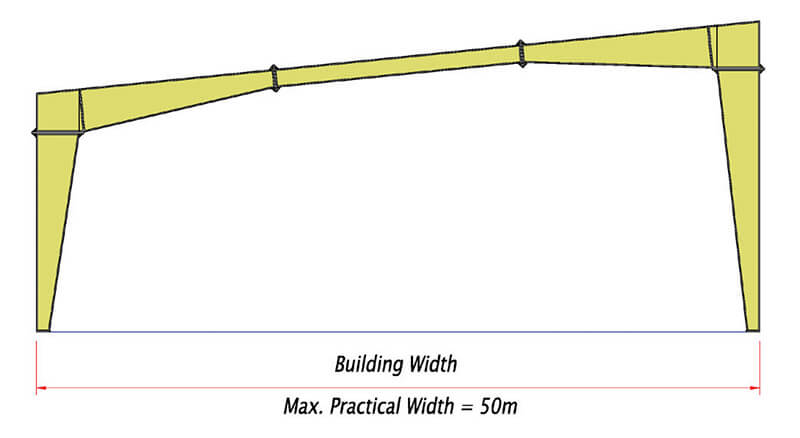

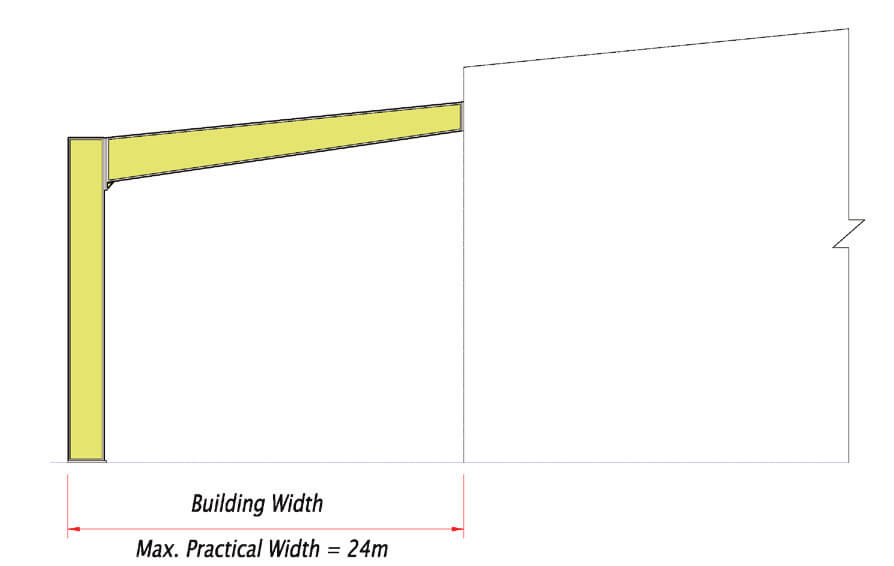

Single Slope buildings are offered with single or multi-span modular options. Straight or tapered columns are available.

Multi Gable Buildings are maintaining a low ridge height for very wide buildings.

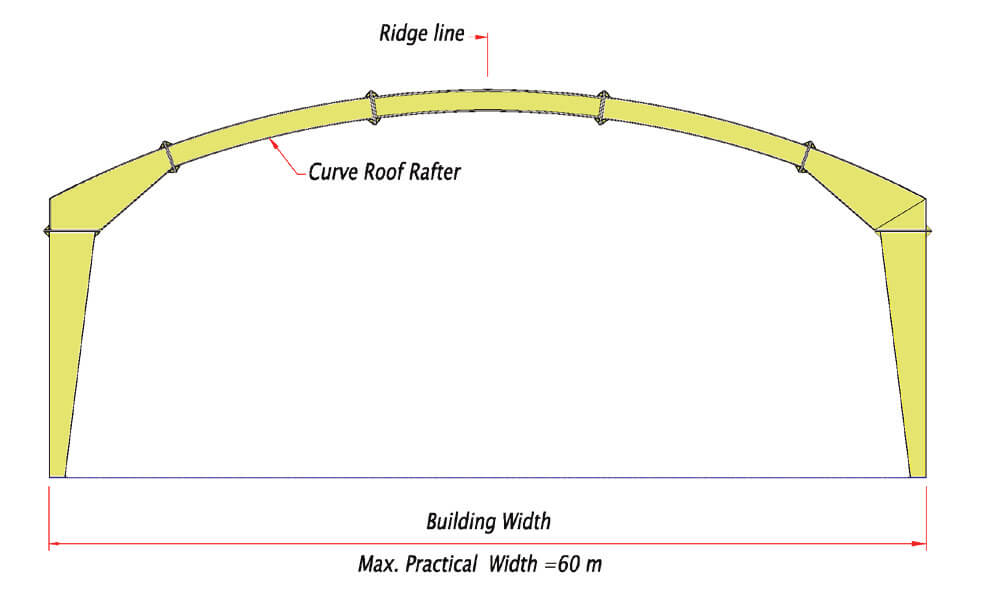

Curved Roof gives special appearance to the building and modular width also can be increased.

Roof System

When Concrete wall exist to support main building, utilizing the support, roof system will be the cost effective solution and more work space to the client can be achieved. However, there will be a limitation on building span.

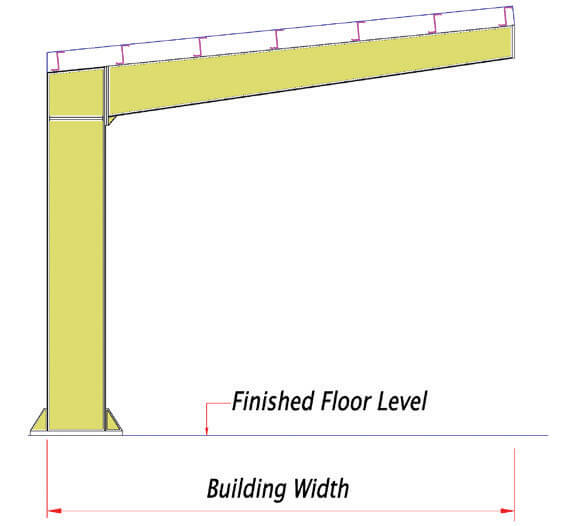

Lean-to and Car Canopies

These building enhancements are ideal for car parking, building expansions. The structure can be made of hot-rolled or built-up sections. Lean-to’s require a supporting structure to take the lean-to reaction.

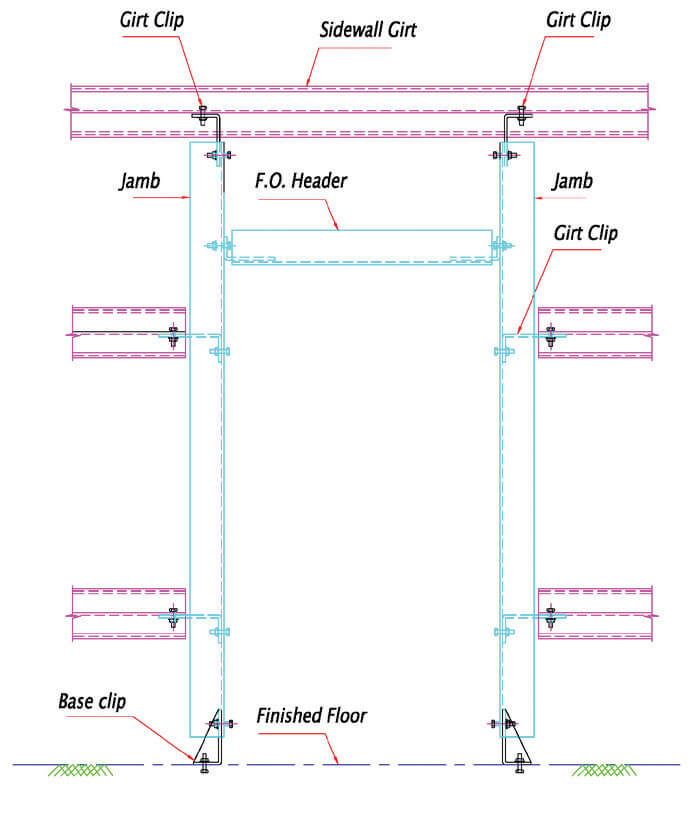

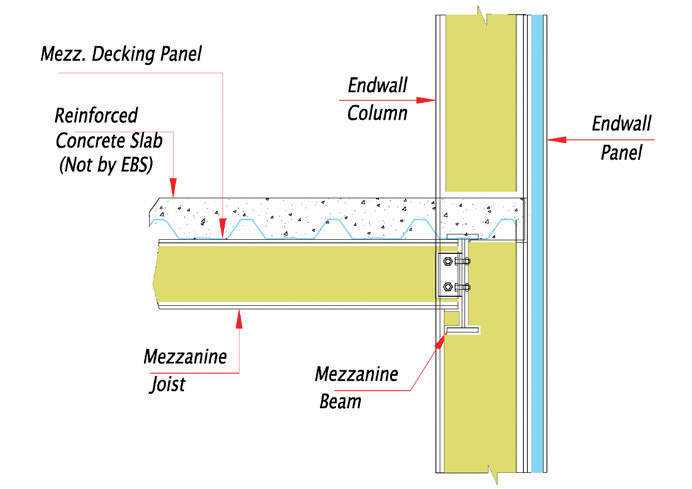

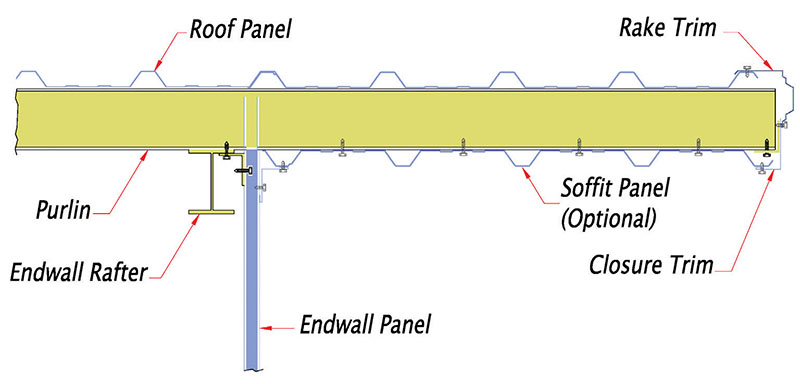

Secondary end wall Frame

Simple end wall frame with pin connected rafter and columns will reduce the building weight and on cost. However, if future expansion of the building is expected along sidewall, Rigid frame should be used at ends. Standard endwall column spacing would be 6 mts. Endwall column and rafter can be made from hot-rolled, built-up or cold form cee. Flush girt are standard feature for end wall framing.

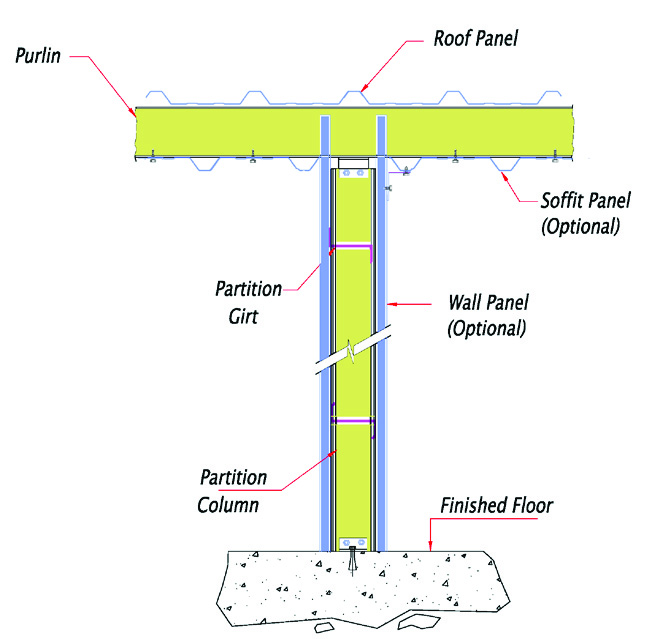

Cold form structure

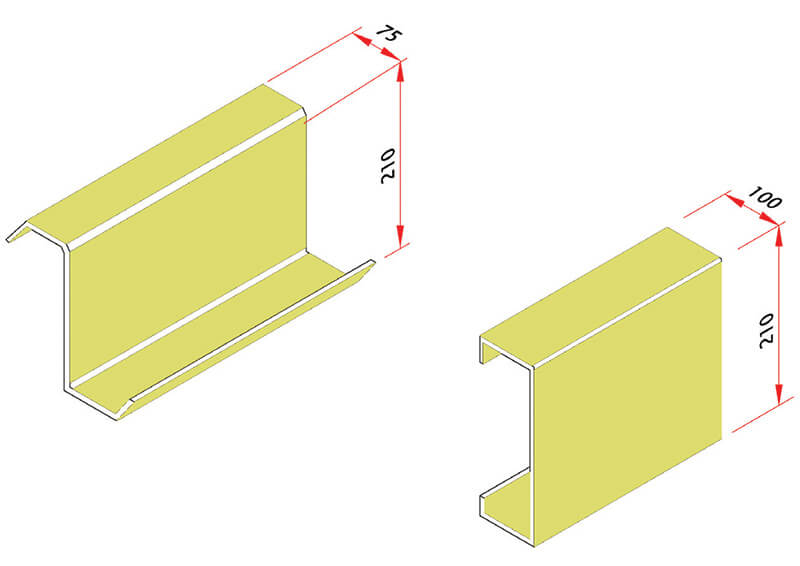

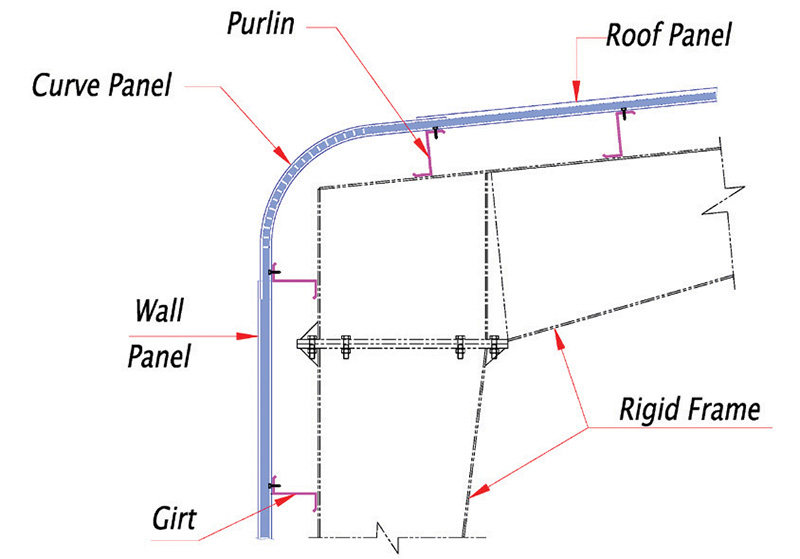

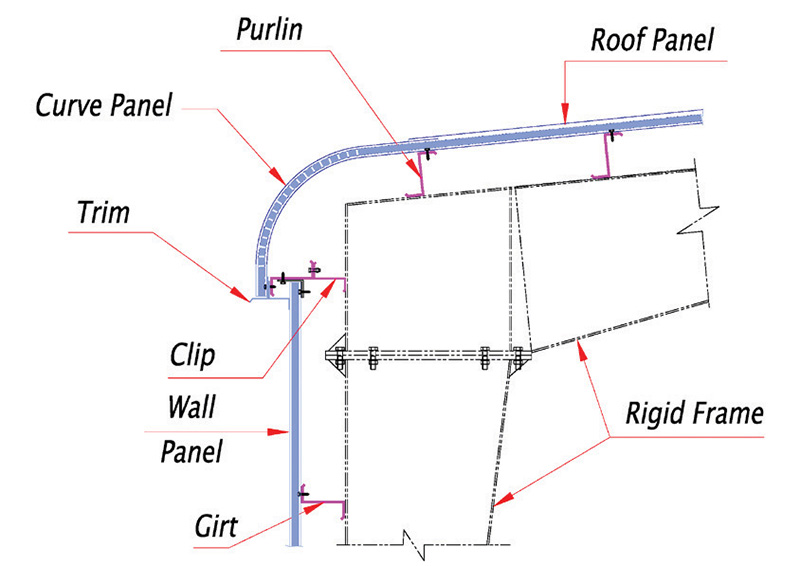

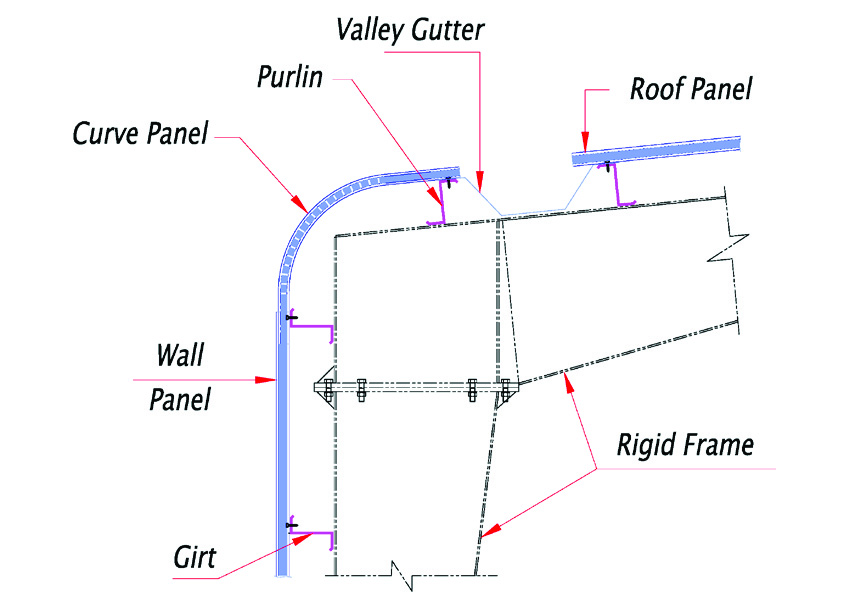

Supporting members for wall and roof panels are girt and purlin. Cold form Zee section is used as purlin and girt. Standard height of Zee and Cee sections are 210mm. However HASANOGLU can supply any depth of Zee and Cee sections ranging from 125mm to 300mm. Cee sections are widely used as frame open members; jamb, header and sills. Also Cee section is used as end wall column and rafter. Main advantage on cold form members are

- As raw material is pre-galvanized, no painting is required and self rust proofing.

- There is no welding involved in the members and production is automated, hence accurate and faster supply of final product is assured.

- Member weight is relatively less, so handling will be very much eased.

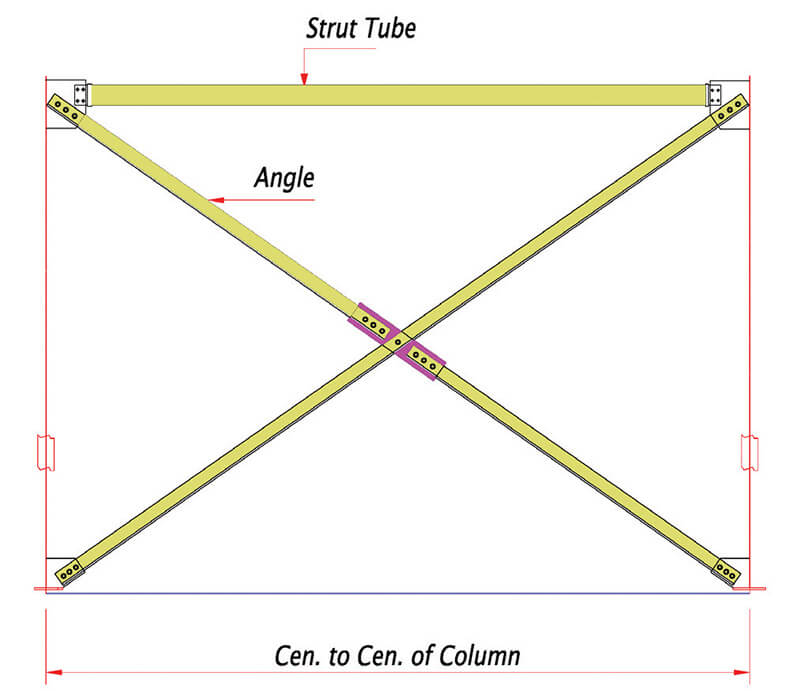

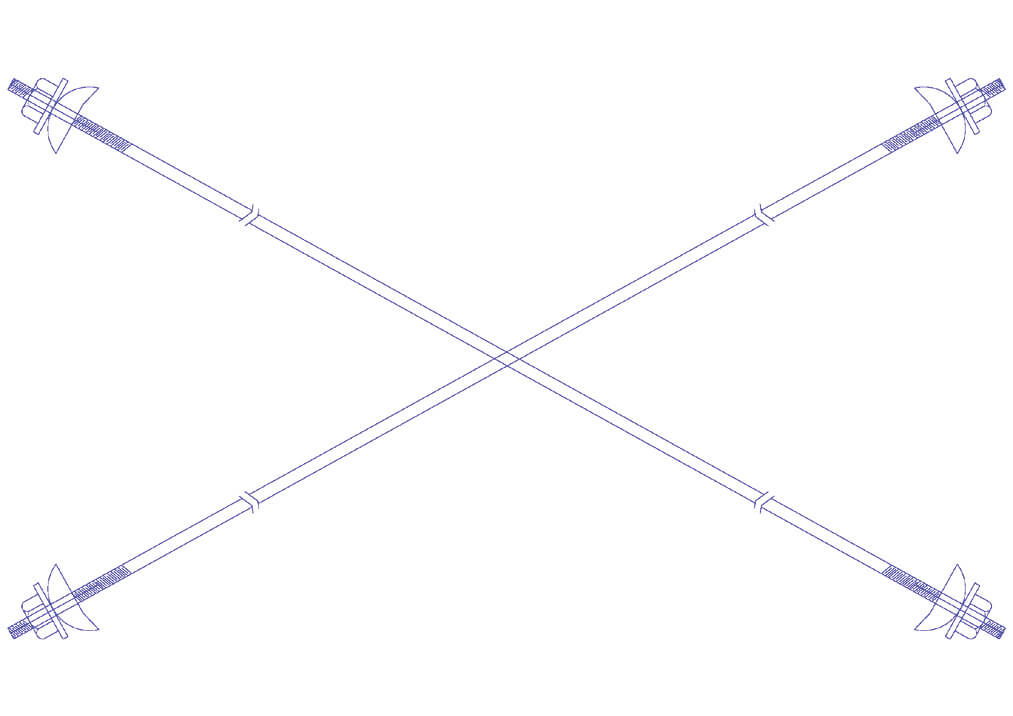

Roof and wall bracings system

Rod and angle shapes are used as bracing members in wall and roof bracing system. End wall framing system carries wind load and transfers them through strut purlin and then bracings to the ground. Standard brace rods are rod dia 12, 16, 20, 25 and 32mm.

Building Subsystems

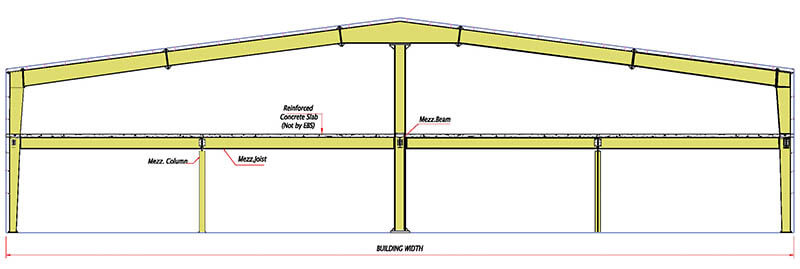

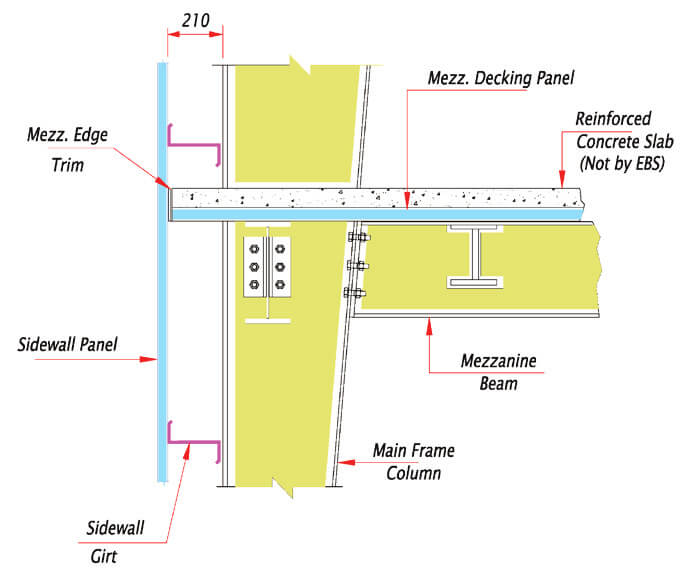

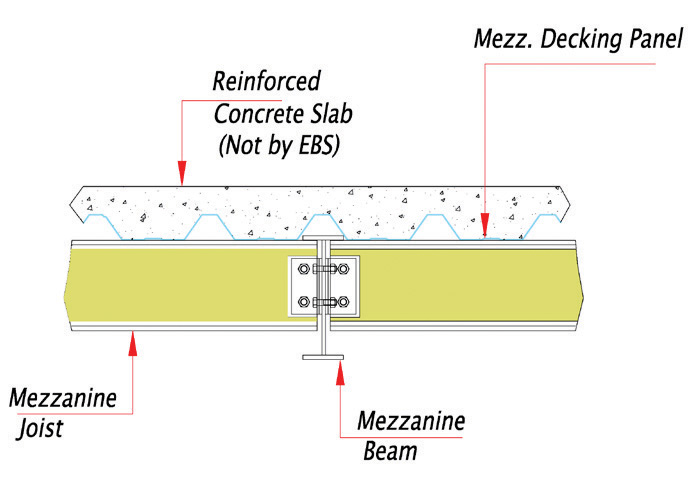

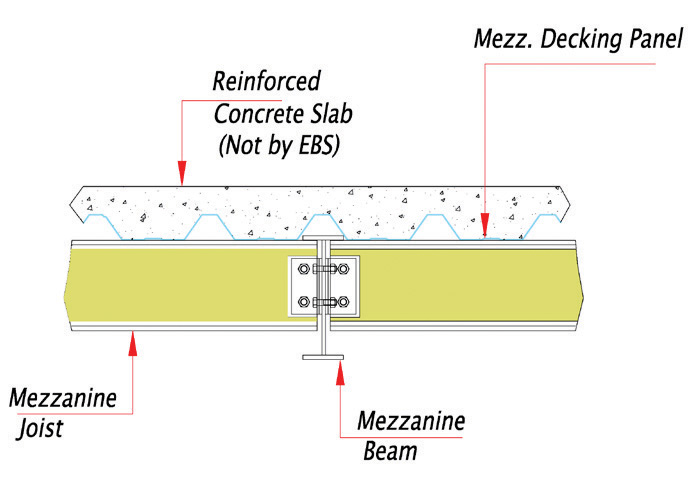

Mezzanine

A mezzanine is an elevated floor for use as office or store area. The mezzanine framing is connected to main frame and intermediate columns for support. The mezzanine framing consists of joists, beams and a profiled steel deck for concrete.

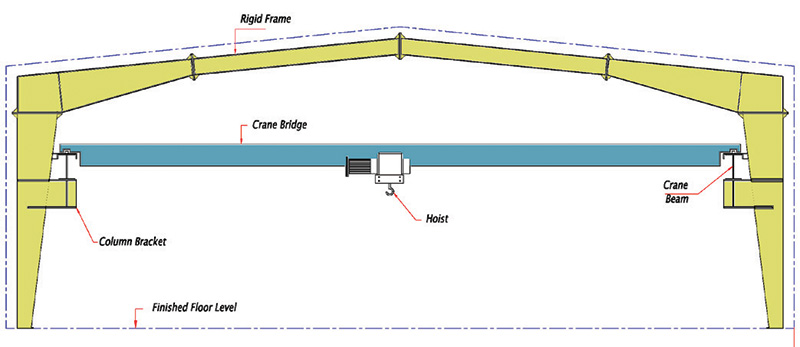

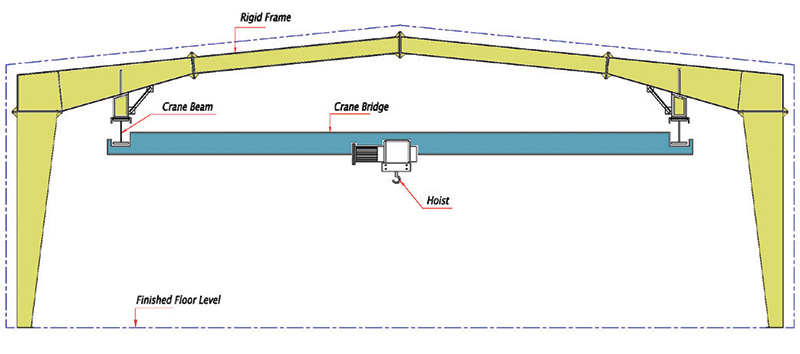

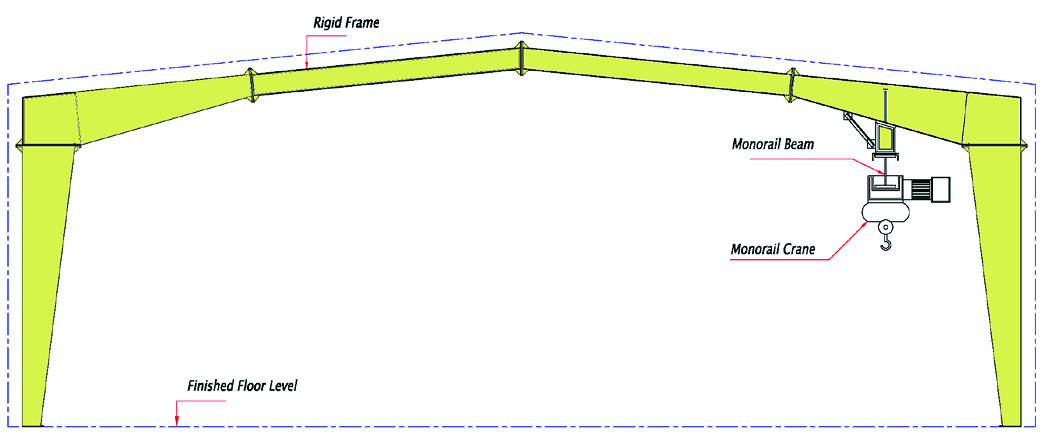

Cranes

A crane system improves material handling efficiency and increases productivity. A crane is a part of any workshop building. HASANOGLU can offer various types of crane systems.

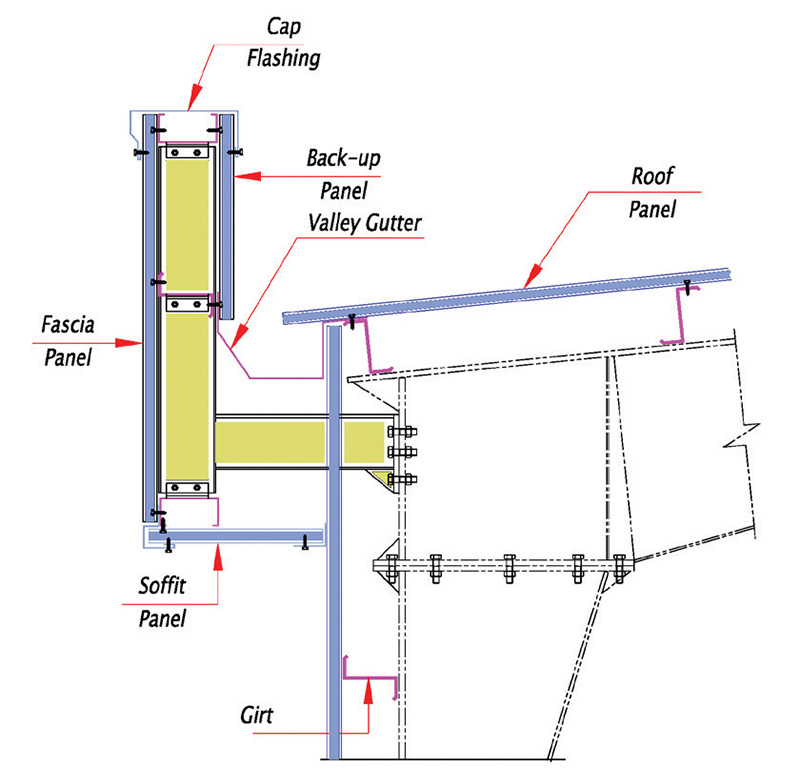

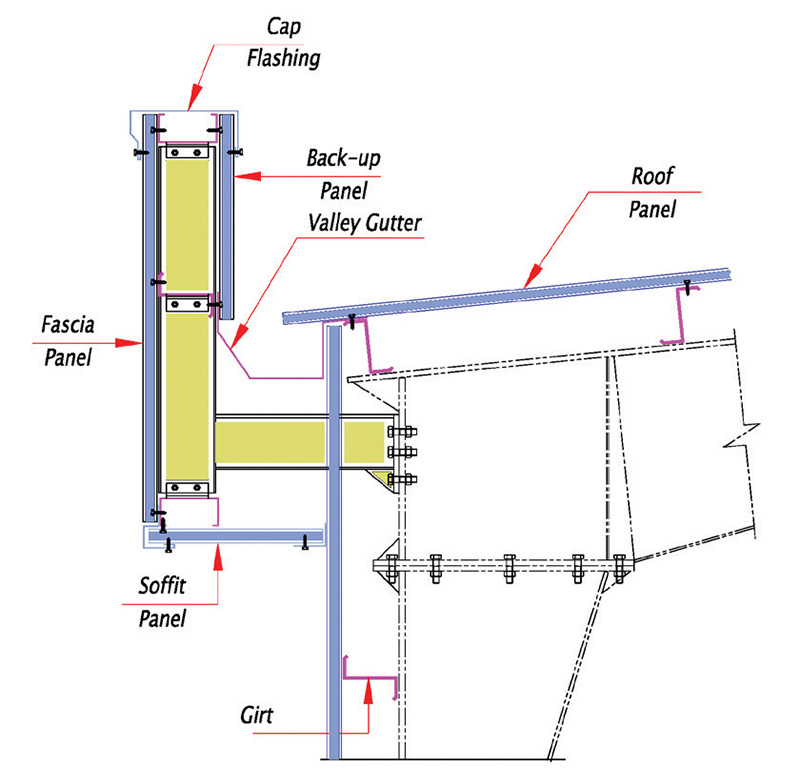

Fascia

Fascia may be designed to project out of sidewalls or endwalls to suit architectural requirements. Parapet fascias are flush vertical extensions of the sidewall and/or the endwall systems of building. The parapet usually extends up to conceal the roof ridge line. It hides small roof mounted mechanical units. The parapet fascia requires a valley gutter with internal down pipes.

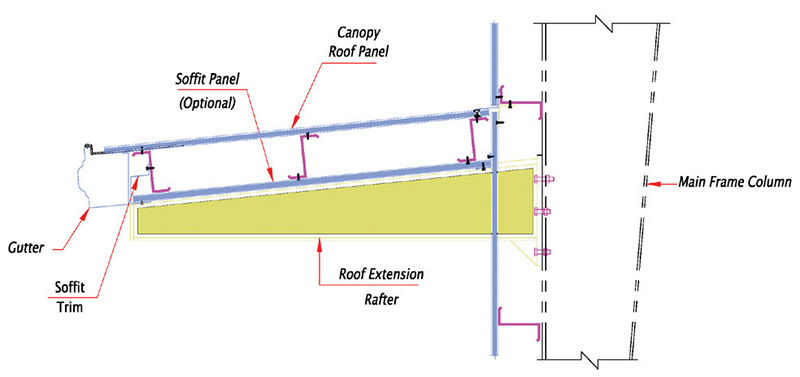

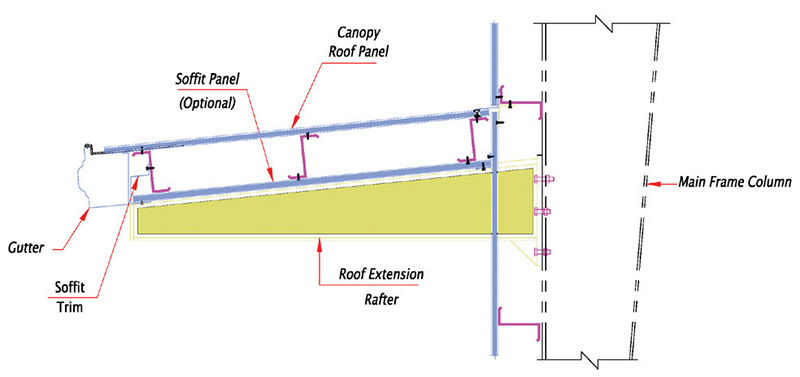

Canopy

Canopy framing provides a sun shade as well as a weather shield. The canopy can be positioned at either the eave or over doorways etc. The canopy cantilever beam requires to be supported by the building frame and can have a tapered or straight profile.

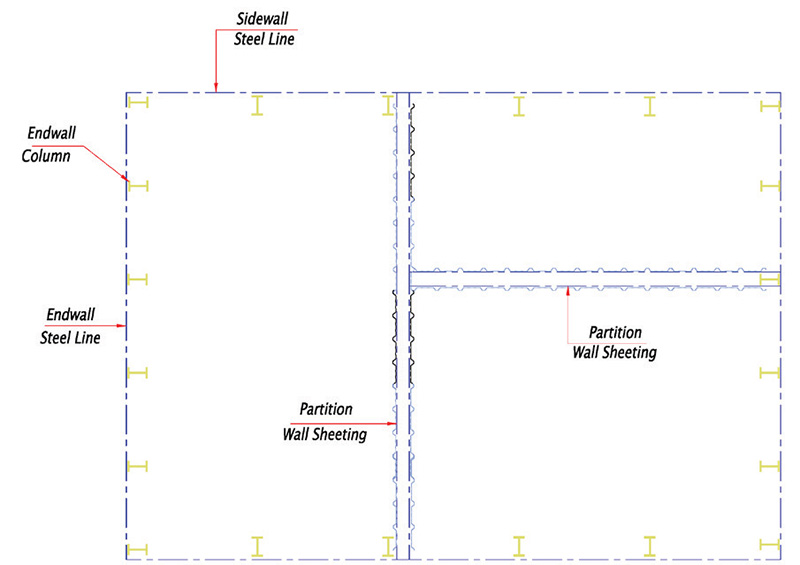

Partition

Light weight internal partitioning provides the customer a means to sub-divide the building interior into structured space to house various activities. Office areas can be separated from process areas.

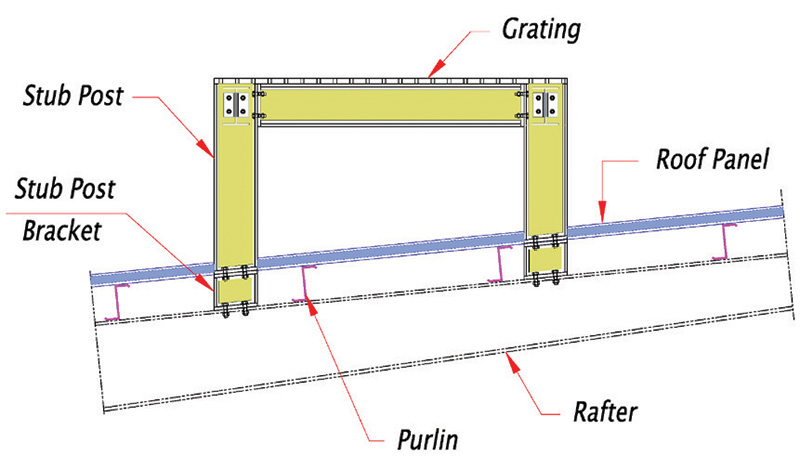

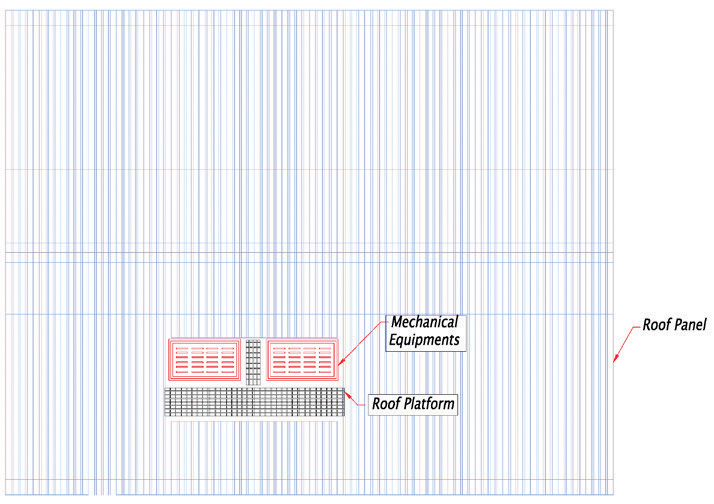

Roof platform

Roof Platform provides a support for heavy mechanical and other equipment. The platforms are mounted on the main frame rafters. The pipe support legs are weather sealed with profiles rubber flashings or stub brackets are provided to connect the column above roof sheeting.

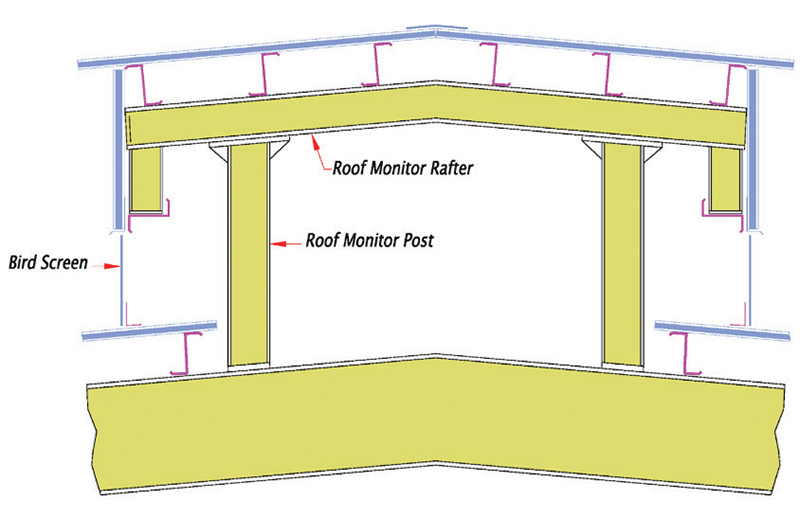

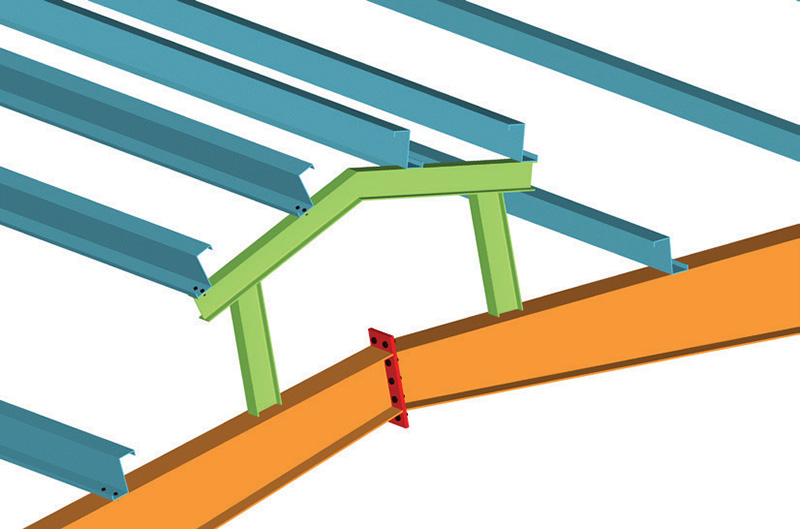

Roof Monitor

Continuous roof monitors provide large ventilation and lighting requirements. They are made from lightweight components and provide a cost effective ventilation and natural light system with pleasant appearance.

Curved Eave

Curved eave will provide elegant appearance to the building. When building width is more and high rain fall, curved eave shall be with gutter to collect water and drain from inside the building. Small buildings, simple curved eave without gutter is recommended. Projected curved eave will give more architectural appearance

Roof Extension

Roof Extensions, when required at endwall nominally 1.0m to 1.5m, the overhang is created from the purlin member extensions with cantilever from the centre of the endwall frame. Trims are furnished at the end of cantilever and soffit panel is added to conceal structural framing.

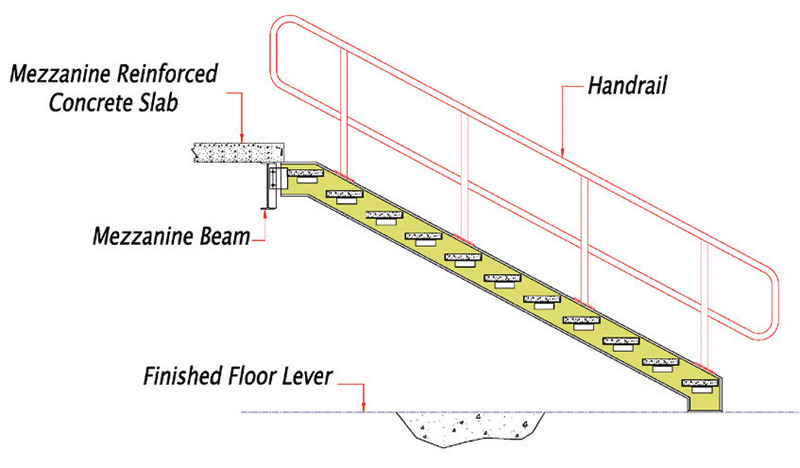

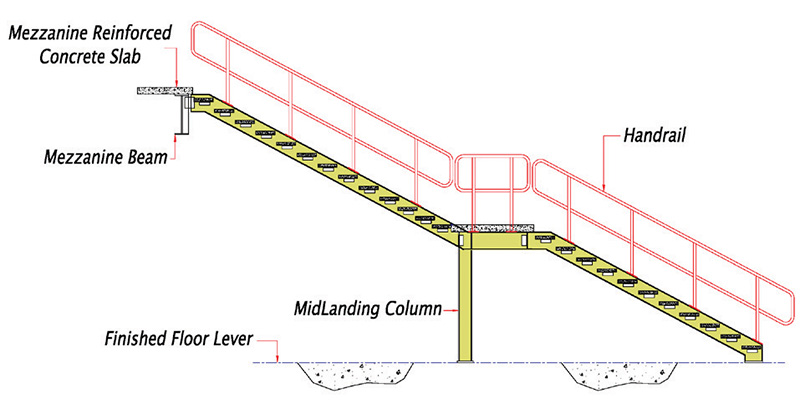

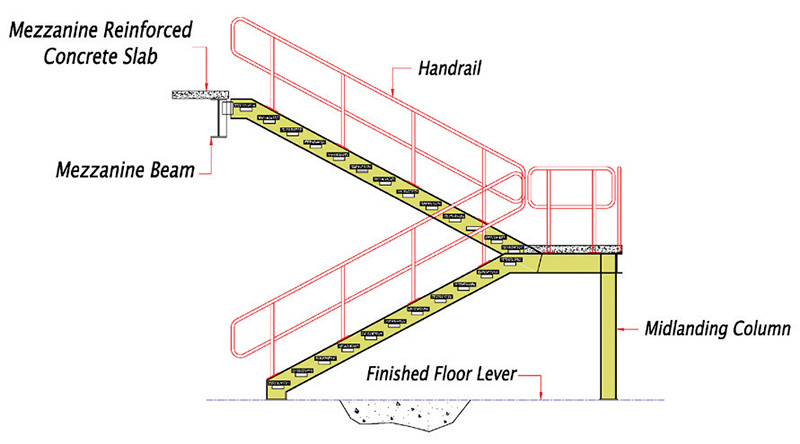

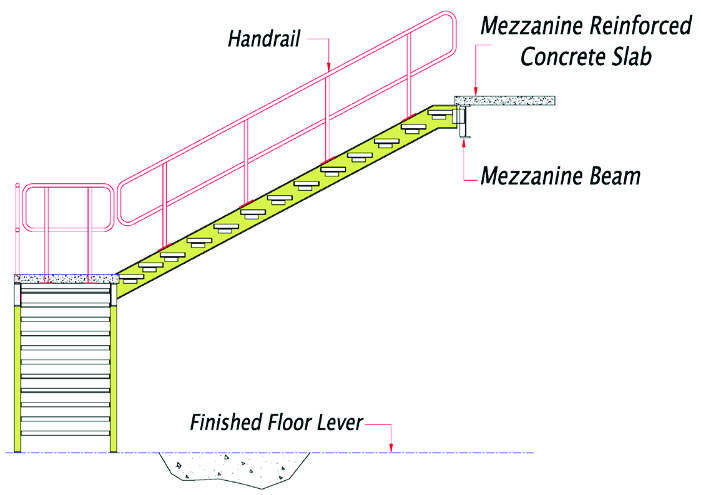

Staircase and handrails

Staircases are used in steel buildings to access mezzanine and areas requiring maintenance. Staircases are of different types like Single Flight, Double Flight and Single Flight with mid landing. All these stairs can be supplied either in chequered plate treads, grating treads, or U-shape treads to be filled with concrete. Non-standard stairs also can be designed and supplied as per architectural requirements.